RESTORING HARDWOOD FLOORS INTELLIGENTLY.

Using advanced technology in sanding equipment – highly efficient dust containment systems – and extremely durable eco-friendly finish applications we strive to provide a unique approach to restoring your hardwood floors to the look and beauty you want and deserve!

Since starting FloorAnthropy in 2007, Josh and his team have restored the hardwood flooring in 100’s of homes throughout Northeast Ohio. Focusing on just wood flooring has given them the ability to perfect their craft as well as stay up to date on the current and coming trends in their field.

“…there are a lot of flooring companies out there that have been set in their ways for a long time; using outdated sanding equipment and harmful, less durable finish practices because they lack the drive to evolve with the times and continue to educate themselves on where this industry is going. The days of smelly oils and dusty machines are a thing of the past – we not only utilize the highest end of machinery but also incorporate more options for aesthetically unique finishes and stains giving us an edge in terms of options and end results.”

- Josh Hammond/Owner

WHY QUALITY EQUIPMENT MATTERS.

If you want the high-end results, we have to invest in high-end equipment! We strive for consistency in every project we tackle – to accomplish that we invest in the right sanders and utilize them for the best results.

COARSE.

Depending on what the situation calls for, we use our Lagler Hummel drum sander on most of the initial rough sanding. Its highly efficient at removing old finishes and leveling out uneven boards.

EDGE.

Where the big sanders don’t reach we tackle the edging with our Lagler Flip and Clarke American Super 7 – both have their roles and are two of the best out there!

FINE.

This is where the good and great floors separate themselves. Our Lagler Trio is THE most effective machine on the market at keeping wood floors smooth, flat, and free from scratches. When done right the look and feel of a #laglertrio floor is unlike any other machine on the market!

DETAIL.

Some situations call for a little fine tuning. Festool is our go-to brand for fine sanding and finishing equipment. The technology and versatility of Festool are second to none and give us the ability to create furniture finishing performance on your floors.

DUST-LESS SANDING.

What does it mean and why it is important.

If you haven’t had your floors refinished in the last 10-15 years (or ever) you might not be familiar with the term “Dustless Sanding”. A lot of customers we meet with are always afraid that if they have their floors sanded it will leave an extremely dusty mess in their House – that’s not the case anymore! We utilize some of the most efficient sanders connected to very strong vacuum systems to ensure that we limit the airborne dust when sanding your wood floors. Most of the equipment we use are equipped with HEPA filters to ensure that fine wood dust is stopped before it hits your house.

“Dustless” vs “Dust-Free”

Many companies will market their refinishing services as “Dust Free” what’s the Difference?

DUST-FREE.

When referring to “dust-free” refinishing this process usually incorporate a machine that cleans your existing floors – maybe lightly abrades – and uses a chemical application to apply new finish to your floor. These systems do work but with this, you are not actually sanding the floor – hence “Dust-free”. We also offer the Dust-free Refinishing and you can learn more about it on our Maintenance Page.

DUSTLESS.

Dustless sanding refers to the sanding of hardwood floors with the utilization of vacuum systems connected the sanders. We like to say that the process is usually 97-98% Dust Free. There will be some residual dust that isn’t always captured but most of that is vacuumed up between our sanding sequences and prior to applying the stains and finishes.

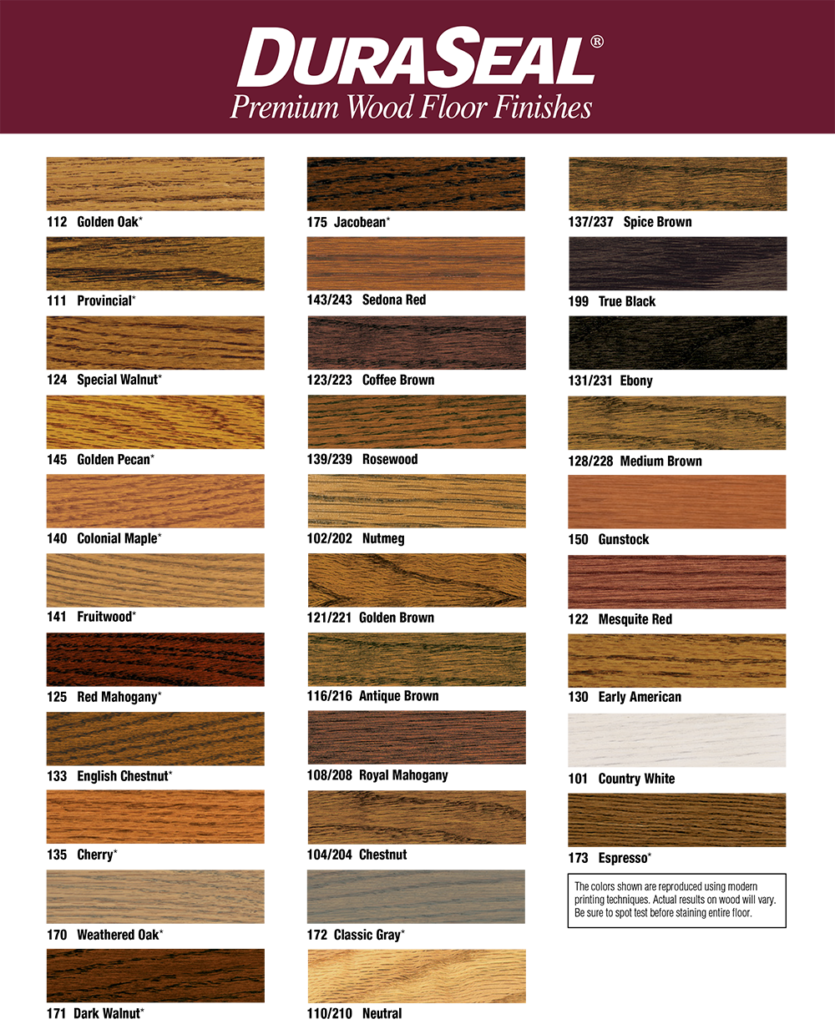

STAIN & FINISH.

UNLIMITED COLOR OPTIONS AND ECO-FRIENDLY FINISHES.

When it comes to the aesthetics and durability of your hardwood flooring, products and process are everything. Every stain and finish system we use on your hardwood floor has been extensively researched and tested to make sure that were not only giving you the best quality stains and finishes but also using products that we know will stay beautiful for the test of time.

Our process of staining and finishing always depends on the situation and variables of the project. Few examples below:

- species of wood

- color to be achieved

- traffic and wear expected

- future maintenance required

- dry times needed

- adversity to chemicals and smells

- budget and cost

We have a few different options when it comes to staining and finishing your floor and they are listed below. These products and process will vary depending on your situation and we can discuss in detail when we do our in-home consultation.

Oil-Based Residential

- High VOC’s

- Matte | Satin | Semi | Gloss

- Low/Medium Traffic Residential

- 7 Day Full Cure Time

- $

Water-Based Residential

- Low VOC’s

- Matte | Satin | Semi | Gloss

- Residential & Light Commercial

- 24-48 Hour Full Cure Time

- $$

Water-Based Commercial

- Low VOC’s

- Matte | Satin | Semi | Gloss

- Heavy Residential & Commercial

- 36 – 48 Hour Full Cure Time

- $$$

Rubio Monocoat

- Zero-Voc

- Matte Finish

- Residential and Light Commercial

- 36 – 48 Cure Time

- $$-$$$